Emboss vs Deboss Differences

Emboss vs Deboss Differences

Embossing and debossing are both custom decoration methods designed to give a product 3D depth. The difference is that an embossed design is raised from the original surface while a debossed design is depressed from the original surface.

The debossing and embossing processes are nearly identical as well. In each process a metal plate, or die, is engraved with a custom design, heated and pressed into the material. The difference is that embossing is achieved by pressing the material from underneath, while debossing is achieved by pressing the material from the front. Embossing and debossing are typically performed on the same materials – leather, paper, cardstock, or vinyl, and neither should be used on heat-sensitive material.

Benefits of Embossing

- Creates a 3D design that pops from surface

- Easier to apply foil stamping to an embossed design

- Can hold finer detail than debossing

- Better for custom stationary, business cards, and other paper promotional products

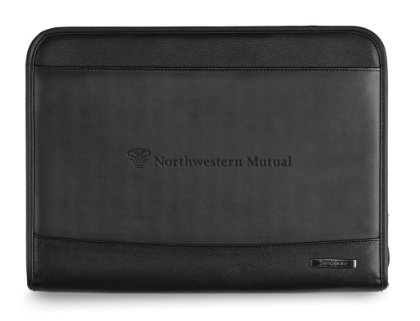

Benefits of Debossing

- Creates dimensional depth in the design

- Easier to apply ink to debossed design

- Back of material is not impacted by a debossed design

- Debossing plates/ dies are typically cheaper than those used in embossing

- Better for custom wallets, padfolios, briefcases, and other leather accessories

Taking it Further

Embossing and debossing have more in common than differences and in most cases, it just comes down to personal preference and design elements. To learn more, check out our complete Debossing Capabilities or dive further into the Custom Debossing Process. Not sure if debossing or embossing are the way to go for your custom accessories? Read up on every way we can apply your corporate logo to custom apparel, accessories and gifts in our Custom Decoration Methods Guide.