Custom Debossing Explained

Custom Debossing Explained

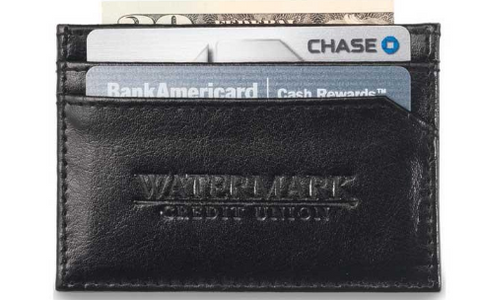

In its simplest form, debossing can be thought of as an advanced form of stamping. A metal plate is engraved with your custom design, heated, and pressed into the material to create a promotional product with dimensional depth. At Merchology, we use debossing to bring your logo to life on a variety of personalised accessories and corporate gifts!

How does Debossing Work?

Debossing might sound simple, but there’s more to it that you might think. First, you’ll want to understand the difference between embossing vs. debossing, as they are two similar decoration methods than produce opposite results. Next, check out the step by step debossing process used by the deboss experts at Merchology below!

Step by Step Guide to Custom Debossing

- Design the Die Template – using graphic design software, we import your logo or custom design, digitize it and save it into a file to be loaded into a CNC machine.

- Engrave the Metal Plate – we use a CNC milling machine in the die-cutting process to cut out your logo or design from the metal plate. In debossing, your design will be the raised part of the metal plate.

- Position the Engraved Plate – the metal plate with your logo on it is locked into place on the press. We use special debossing presses to maximize efficiency and consistency across orders.

- Heat the Plate – we fire up the debossing machine and heat your metal plate to about 212 °F, or 100°C.

- Position the Product – your product is loaded into position on the press by one of our debossing experts. Remember, debossing works best on leather, paper, and vinyl!

- Press the Product – the metal plate is lowered onto the product and heat and pressure work together in unison to create the indented design. A lot of pressure is required to drive your logo deep enough into the material to create a permanent design!

- Allow the Material to Cool – your product is going to be hot! Give it some time to cool before handing it.

- That’s a Wrap – the debossing is now complete! Next, we check each product for quality before packing them up and shipping them right to your door.

What Equipment and Supplies are Needed for Debossing?

When done properly, debossing requires a variety of expensive machines that make it infeasible for non-commercial applications. However, if you’re starting your own commercial debossing operation we’ve got your starter pack right here.

- Computer + Design Software – a computer with graphic design software is needed to digitize your logo before it’s uploaded to the die-cutting machine.

- Engraving Machine – an engraving or die cutting machine, like a CNC milling machine, is used to add your company logo or custom design to the metal plate.

- Metal Plates – these are engraved, heated, and stamped onto your product to create the depressed area of your design. These are also called debossing dies and are typically made of magnesium, copper, brass, or steel.

- Debossing Machine – this is the machine in which your metal plates and products are positioned in. It works sort of like a printing press, using both pressure and heat to create your design.

- Ink/ Foil – this one is optional! Debossing is a very versatile decoration method and can be used in concurrence with other decoration types like custom printing and foil stamping. If you choose to go this route, be sure to acquire the necessary materials!

Next Steps

Debossing is a stylish alternative to other more common printing techniques and is a great way to set your branding apart from your competition. If you think debossing is the right custom decoration type for you be sure to check out our complete Debossing Capabilities. Still not sure? Contact us or take a look at our comprehensive Custom Decoration Methods Guide where we outline each decoration type we use at Merchology.